A Brand New Generation Of Coatings

Phosphating replacement and Zinc Plating enhancement for critical fasteners in an innovative waterborne dry-to-touch lubricated polymer

Features and Benefits

A World of Benefits

Application

Introduction

Water based mixture of thermosetting resins.

Applications

TP-COTE® is mainly used as anti-corrosion coating for metal industrial

applications in the automotive field. TP-COTE® has been developed for dipping

applications and single-coat stoving. A double layer configuration is also possible.

This product cures at temperature around 170°C and timing not less than 12 min.

Solid Content

40 - 50 ISO 3251

Viscosity (Ford cup nr.4 at 20°C)

s 30 – 50 UNI EN 535

Special Properties

TP-COTE® offers excellent corrosion resistance to the metallic substrates

and low friction coefficient. By using TP-COTE® the metallic substrate is not

subject to Hydrogen embrittlement due to acid cleaning and/or galvanic processes.

Packaging:

25, 200 Kg metal tanks or 1000 lt. IBC container

Storage

TP-COTE® must be stored in a cool, dry, well ventilated place and containers have

to be tightly closed. Avoid frost and store it at temperature in the range 5 - 25°C.

Handling

For all the safety precautions and transportation regulations refer to the related MSDS.

Properties and Uses:

TP-COTE® has to be kept in the original container which remain closed

until the application.

TP-COTE® has a shelf life of 12 months but for rheological matter it’s

suggested to use it within 3 months.

It may happen, for tixotropic behavior, an increased viscosity above the

upper limit of 50 sec., suggested for dipping application, even the

product is within the shelf life.

In such a case the product must be vigorously stirred for few minutes, without

creating foam, in order to increase the fluidity.

This operation is in any case always recommended.

In case of long storage time it could be necessary to dilute the product with

alkaline deionized water. Usually 5% of dilution it’s enough to bring the viscosity

at the original value. Before to do such operation we recommend to check the

correct way by consulting Tecnopolimeri’s people.

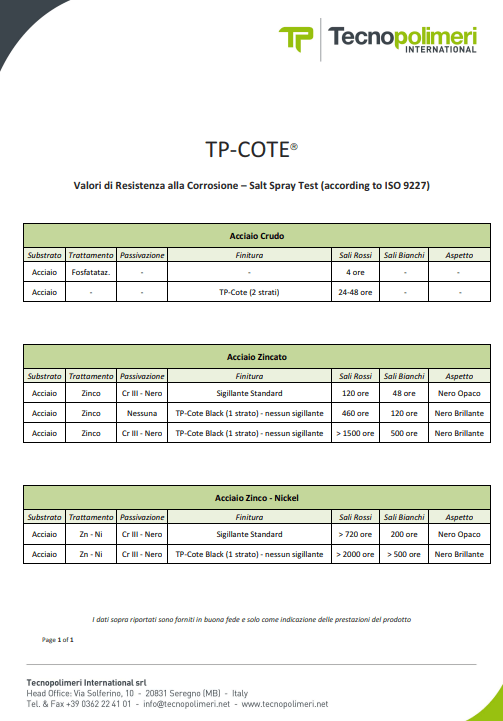

Corrosion Resistance

FCA Certified

Download Center

Contact

We would be glad to have your feedback.

Call us at +39 0362 224101 or send an email using this form. We'll be back to you quickly